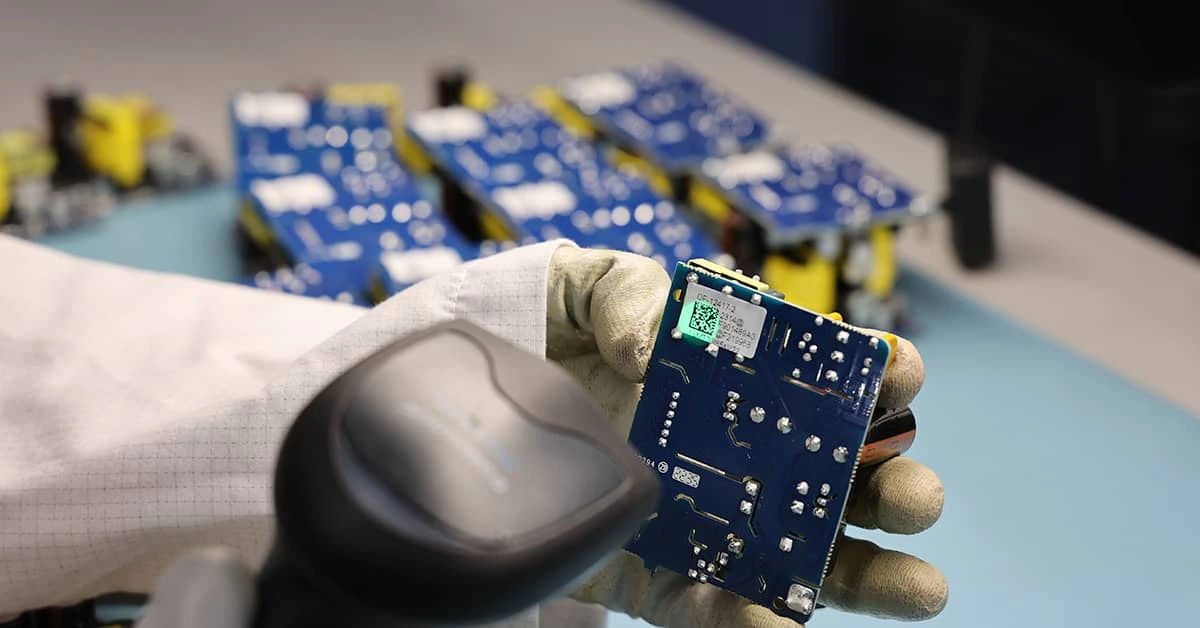

MANUFACTURING PROCESS THAT EMPHASIZES TRACEAVILITY AND PRODUCTION CONTROL

We take pride in offering a manufacturing process that emphasizes traceability and production control, with a software that allows us to monitor product quality at every stage of the process and maintain accurate historical records.

With component-level traceability, which means we can identify the supplier batch used in each electronic board and maintain a record that our customers can consult whenever needed. With this traceability and production technology, we can provide accurate delivery estimates and real-time updates on the status of manufacturing.

Definition of technology

Traceability is essential in the electronics industry as it ensures the quality and reliability of products throughout the entire production chain. Some of the key advantages of traceability are:

- Improved efficiency and productivity

- Enhanced product quality and safety

- Cost reduction and shorter production times

- Error management

Improved efficiency and productivity

Quick identification of issues and improvement of production processes, leading to increased efficiency and productivity within the company.

Enhanced product quality and safety

Detailed record-keeping of each component and manufacturing process, facilitating the identification and correction of potential errors and improving the overall quality and safety of the final product.

Cost reduction and shorter production times

Traceability enables more efficient resource management, resulting in reduced production costs and faster delivery times.

Error management

Component-level traceability allows us to establish a clear relationship between the supplier batch and each electronic board we manufacture.

We offering comprehensive and detailed traceability of our products and production processes

Traceability is a key tool in delivering quality products and exceptional after-sales service.