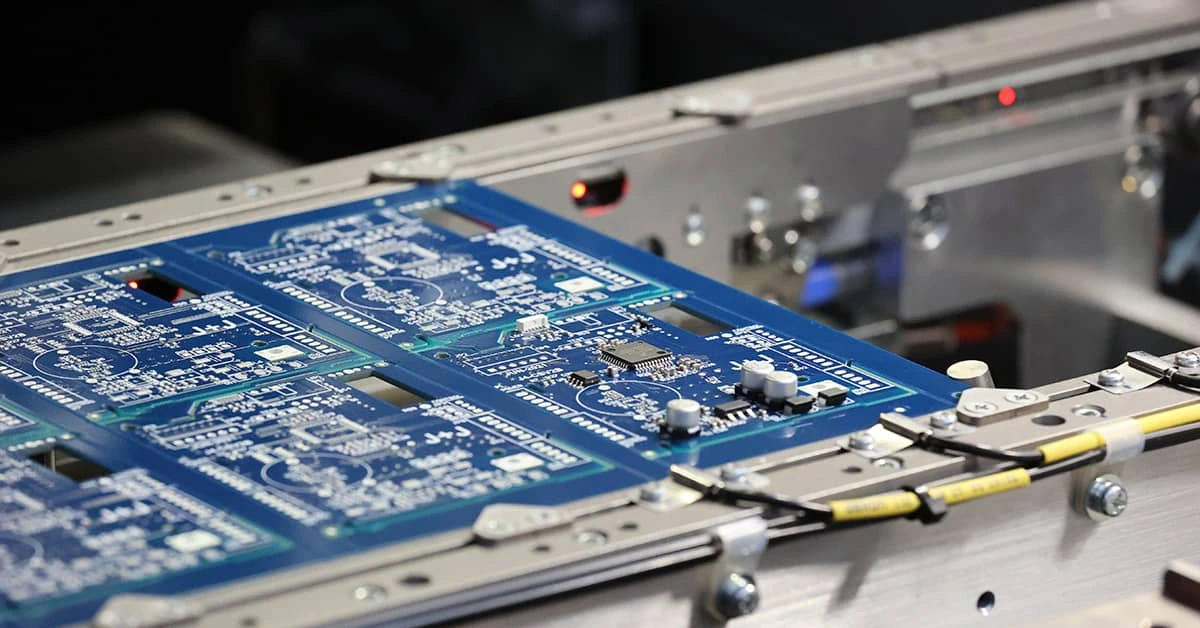

ARE EQUIPED WITH AN AUTOMATED SURFACE MOUNT ASSEMBLY LINE

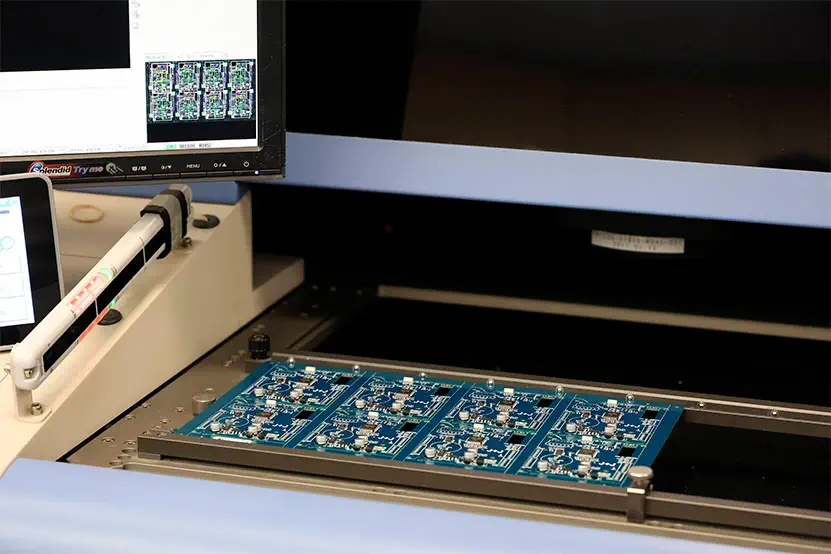

Allowing us to provide an agile and efficient service in the production of high-quality electronic boards. Additionally, we have an optical-digital inspection system to ensure precision at every step of the process.

At Clautronic, we are committed to customer satisfaction and we adapt to their needs, from prototyping to mass production. We have no minimum production requirements, enabling us to work on projects of any size.

Definition of Technology

Surface Mount Technology (SMT) is an advanced method of assembling electronic boards that involves placing components directly onto the surface of the printed circuit board. This technology offers numerous advantages compared to conventional assembly methods.

- Higher component density

- Faster production speed

- Greater precision in component placement

- Increased strength and durability

Higher component density

SMT allows for the placement of smaller and closer components, increasing the component density on the electronic board. This, in turn, enables greater functionality in a smaller space.

Faster production speed

Our automated surface mount assembly line allows us to produce electronic boards at a higher speed, enabling us to meet tight deadlines and respond quickly to the needs of our customers.

Greater precision in component placement

SMT technology utilizes optical-digital inspection systems that ensure precise component placement on the electronic board. This results in higher quality and reliability of our products.

Increased strength and durability

With components soldered directly onto the surface of the board, the holes used in conventional assembly methods are eliminated. This reduces the possibility of connection failures and enhances the mechanical strength of the electronic board.

Continuous improvement and innovation in our production processes.

At Clautronic, we offer a quality, personalized service to meet the needs of our customers.